Architectural Steel Roofing and Cladding Profile

TRS Standing Seam Architectural Steel Roofing and Cladding

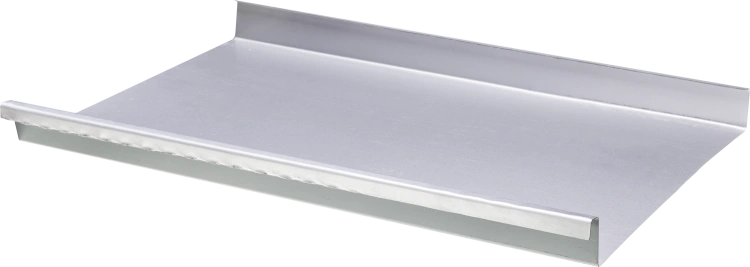

TRS Standing Seam

TRS Standing Seam is a wide tray roofing system. It is fixed to solid substrates such as plywood or timber sarking. Standing Seam is an ideal cladding solution for roofs, façades, soffits, and fascia areas. Drawing on traditional European techniques, it enhances the style and sophistication of any structure. The trays are seamed together using various seam and cap methods. These methods are selected based on functional and aesthetic requirements.

Standing Seam offers significantly more flexibility than other metal cladding options. Shapes can range from standard parallel trays to conical trays with either straight or curved sheets. With suitable materials, it is possible to create complex designs. These include turrets and curved roofs, enabling the customisation of any building’s appearance.

Application

Areas of application could include:

- Roof

- Facade

- Turrets

- Domes

- Soffits

- Fascias

Standing seam is also ideal for creating features such as:

- Chimney cladding

- Flashings

- Interior feature walls

- Pillar and column surrounds

- Gable canopies

Seam Options

Standing Seam is available in a variety of profiles. We offer four of the most popular options: Angle Seam, Double Standing Seam, Roll Seam and Roll Cap. These profiles are flexible in design, cost-effective to manufacture, and easy to install.

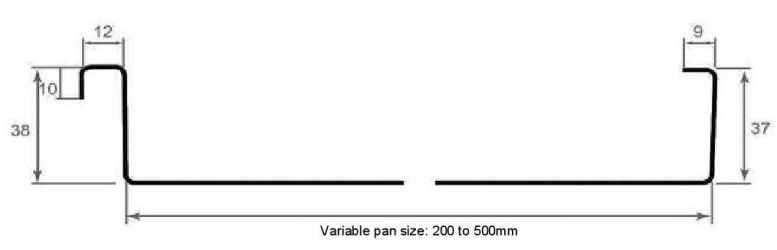

Angle Seam

Suitable for wall cladding and roofs with a minimum pitch of 3°

Variable pan A from 200 to 500 mm

Seam height – 1 ½ inch (38.1 mm)

Minimum panel length – 500 mm (0.5 m)

Only can be manufactured in the following materials:

- Copper

- Zinc

- Aluminum

- Vitor+, Vitor+ ZX or Lux

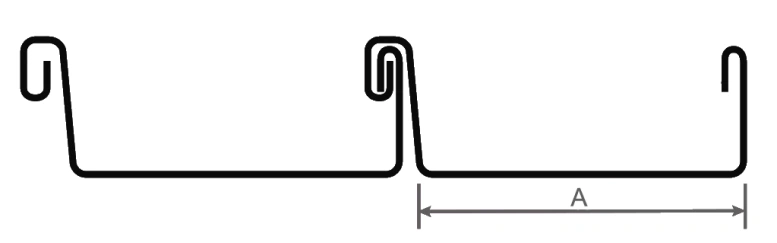

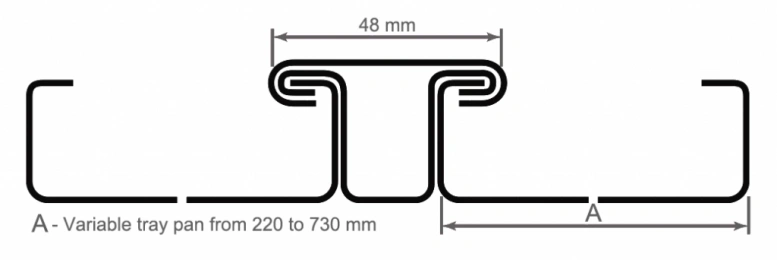

Double Standing Seam

Suitable for wall cladding and roofs with a minimum pitch of 3°

Variable pan A from 230 to 730 mm

Seam height – 1 ½ inch (38.1 mm)

Minimum panel length – 500 mm (0.5 m)

Only can be manufactured in the following materials:

- Copper

- Zinc

- Aluminum – ONLY selected brands. Please consult with us

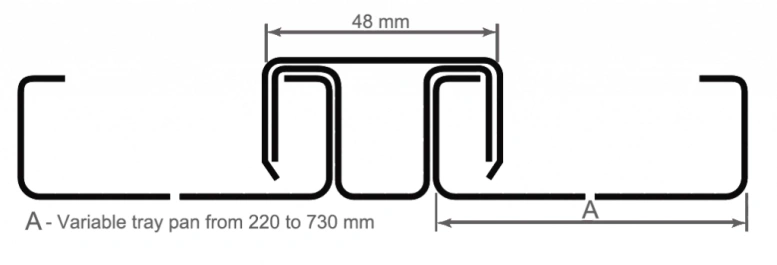

Roll Seam

Suitable for wall cladding and roofs with a minimum pitch of 3°

Variable pan A from 230 to 730 mm

Seam height – 1 ½ inch (38.1 mm)

Minimum panel length – 500 mm (0.5 m)

Only can be manufactured in the following materials:

- Copper

- Zinc

- Titanium

- Aluminum

- Vitor+, Vitor+ ZX, LUX

Roll Cap

Only can be manufactured in the following materials:

- Copper

- Zinc

- Titanium

- Aluminum

- Vitor+, Zenex+ ZX, LUX

See below for TRS Standing Seam product specifications and downloadable files:

Please note: all colours are available in 0.40mm. Colours marked with * are also available in 0.55mm.

Colour & Finish Options – Lux

Please note:

All Lux finishes are available in 0.55mm base metal thickness, Grade G300, and are suitable for a wide range of architectural roofing, internal and external wall claddings, rainwater goods, and general applications.

While every effort has been made to match the displayed colours as closely as possible to the true colours, digital colour limitations may result in slight variations. For an exact colour match, please request a physical colour swatch from your local store.

Some profiles may have a limited colour range. For more information, consult with your local branch.

You can find the nearest local store by clicking here.